Product Categories

Tricone Drill Bit

Overview

With the complexities and challenges of drilling in oil & gas filed, Feilong Retop has developed a line of roller cone bits well suited for these applications.

A complete and professional production process ensures each part of rock bit is produced strictly to meet customers' expectations.Through technological advancements in seal, bearing, compensation, cutting structure, and hydraulics coupled with proprietary bit design capabilities. This advanced roller cone provides industry leading reliability and drilling performance.

Advantages

- High reliability of Bearing and Seal

- Efficient Cutting Structure for improved bit life

- Application specific solution

- Increased bit cleaning

- Advanced compensation system

- Drill efficiently in longer, uninterrupted runs

- Enhanced Cone Protection for maximum abrasion resistance

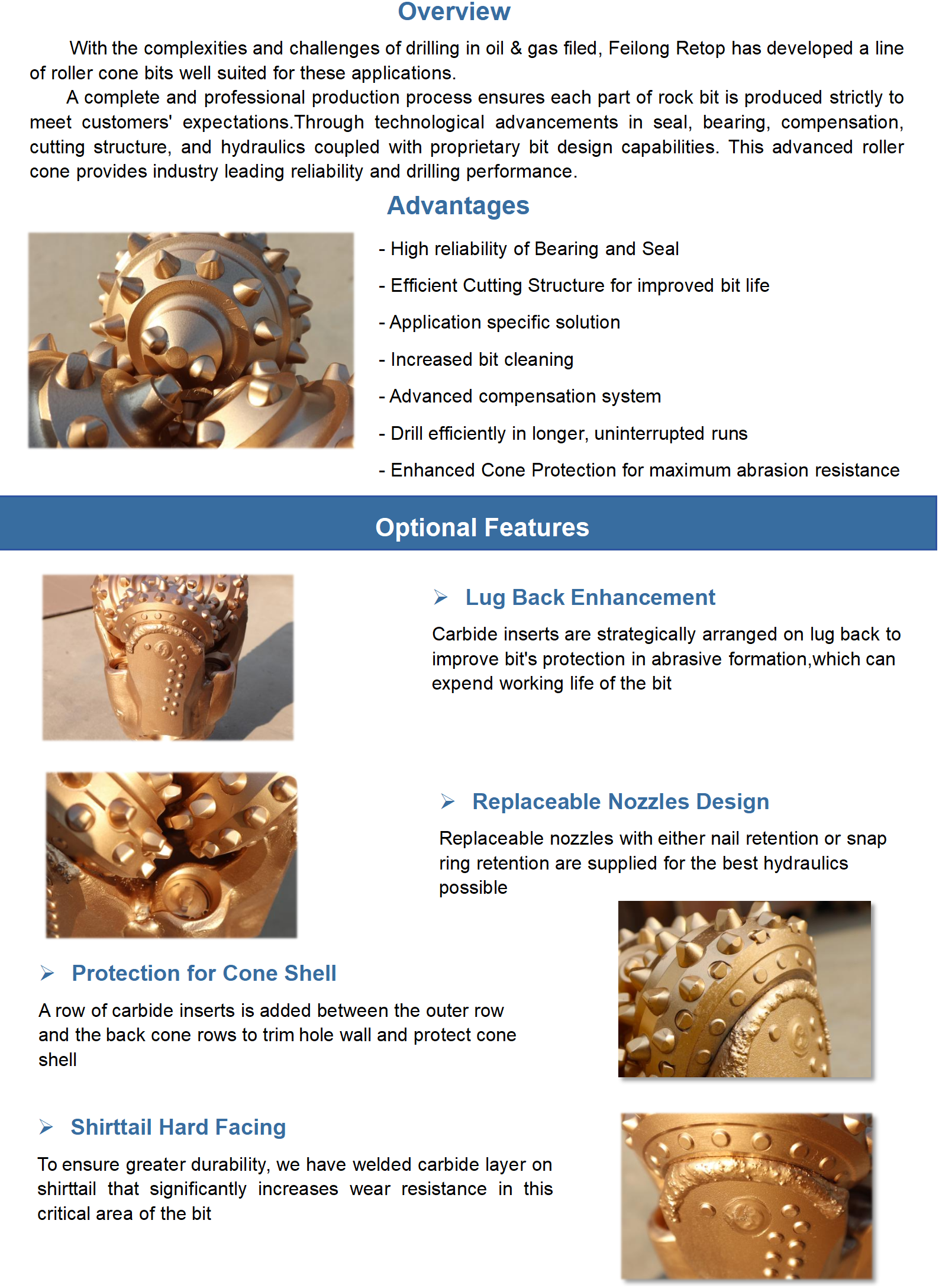

Lug Back Enhancement

Carbide inserts are strategically arranged on lug back to improve bit's protection in abrasive formation,which can expend working life of the bit

Replaceable Nozzles Design

Replaceable nozzles with either nail retention or snap ring retention are supplied for the best hydraulics possible

Protection for Cone Shell

A row of carbide inserts is added between the outer row and the back cone rows to trim hole wall and protect cone shell

Shirttail Hard Facing

To ensure greater durability, we have welded carbide layer on shirttail that significantly increases wear resistance in this critical area of the bit

Intent form

Explanation of Enquiry

Contact information

What products can we provide

Click here to find products quickly.

contact information

Address: Junziguan Industrial Zone, Xicun Township, Hejian City, Hebei Province

Service Hotline:0317-3211668

Copyright: Hejian City Feilong Retop Rock Bit Manufacture Co., Ltd

International Trade Department

Address: Room B2-0645, Century Tea Trade Building, Malian Road, Xuanwu District, Beijing

Phone: 010-63405086 Fax: 010-63407657

Email: market.01.feilong@gmail.com

0317-3211668

0317-3211668

contact us

contact us